Leading with science

We rigorously test biosolids' physical, chemical, and microbial properties at our treatment plants to ensure they meet regulatory requirements and remain high quality. Our monitoring program goes beyond federal, state, and local regulations and is checked for safety and effectiveness by the U.S Environmental Protection Agency and Washington State Department of Ecology.

Loop® is a natural soil amendment produced by extracting carbon and nutrients from wastewater. Better for the environment than conventional fertilizers, Loop returns essential nutrients to the soil where it's applied. Loop also reduces runoff and erosion with its proven ability to hold rainwater like a sponge.

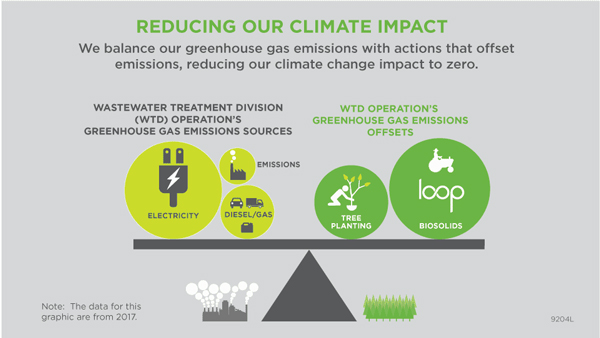

University scientists found that applying Loop to soil stores carbon and reduces greenhouse gas emissions. These carbon offsets outweigh the emissions associated with the transportation of Loop and help offset the energy consumption associated with treating wastewater.

Product quality and safety

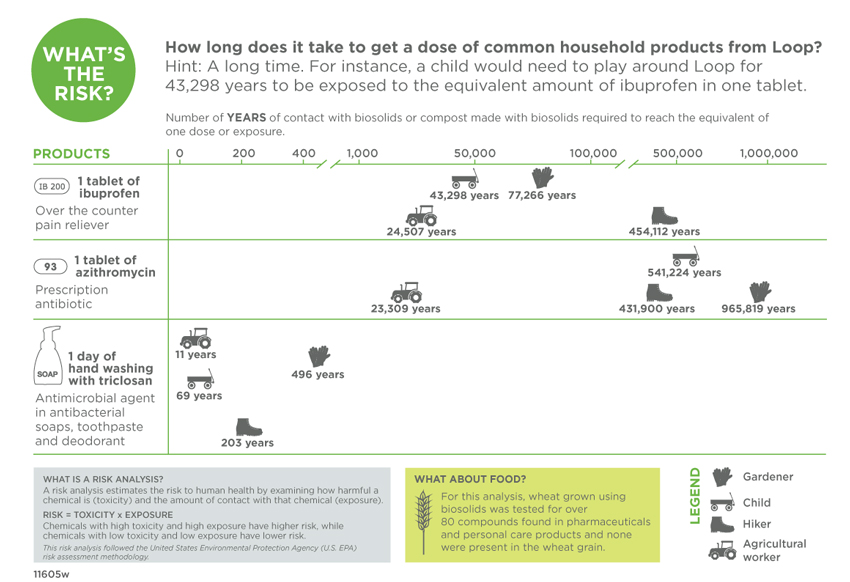

Chemicals are everywhere in our environment. From the medication we take and the products we put on our skin to the material in our homes. As a result, trace amounts of chemicals from pharmaceuticals and personal care products end up at our treatment plants and eventually in our biosolids.

These chemicals are present in such tiny amounts that it would take hundreds, even thousands, of years working directly with biosolids products to match what we are exposed to every day in most household products.

Less than 3% of the flow into our treatment plants is from industrial sources. To protect the quality of Loop, we also work with local businesses to make sure metals and chemicals stay out of the sewer. As a result, Loop contains minimal metals—far less than the regulatory standards and similar to other soil products on the market.

Annual Loop quality data

To ensure the safety and efficacy of Loop, we routinely monitor its physical, chemical, and microbial characteristics.

This is our annual summary.

Addressing forever chemicals

What exactly are PFAS? PFAS stands for per- and polyfluoroalkyl substances, often called forever chemicals because of how long they could take to break down.

These manufactured chemicals are used to make common consumer and industry products, with the most widely known being firefighting foam. PFAS can move through soils and water and build up in fish and wildlife. Human exposure to these chemicals can happen when people eat or drink contaminated food and use PFAS-containing products.

Sampling wastewater

In addition to the state and federally regulated contaminants that we routinely measure in our biosolids, we will be conducting a yearlong PFAS sampling project on wastewater, landfill leachate, and biosolids in a voluntary effort to better understand PFAS levels in our system.

PFAS and biosolids

Biosolids are not a source of PFAS, but will contain detectible amounts of these chemicals due to their extensive use in common household products. Biosolids from areas where PFAS are manufactured are likely to have higher amounts than biosolids from areas primarily serving residential areas. There are no PFAS manufacturers in Washington state.

It’s important to note that PFAS are not a problem caused by wastewater treatment. They are one of many chemicals of concern that come from consumer products, medicines, processes, and other sources upstream of our wastewater treatment plants.

The fastest, most effective, and least expensive solution is source control, which refers to preventing these toxic chemicals from entering our waterways to begin with.

You can find answers to important questions about PFAS and biosolids here.

Product performance and markets

University of Washington (UW) conducted the first trials of biosolids in the woods of Western Washington in the late 1980s, which resulted in 5% to 35% bigger trees. We have been applying Loop in the woods ever since.

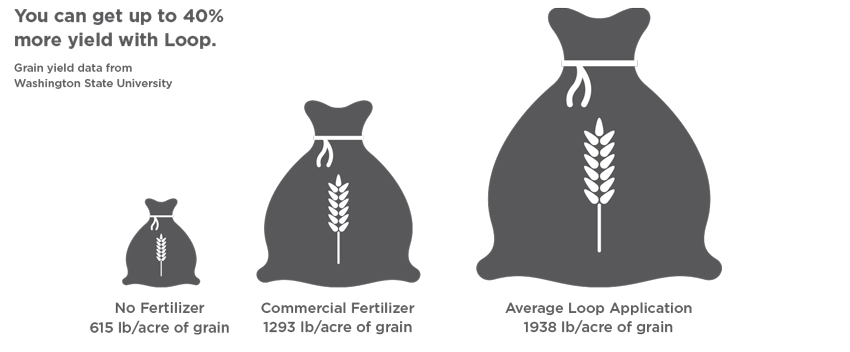

Together with researchers at Washington State University (WSU), we have been studying the impact of biosolids on crop production for over 30 years. WSU soil scientists have confirmed that fields amended with biosolids produce crop yields equal to or better than those treated with synthetic fertilizer.

Environmental benefits and climate

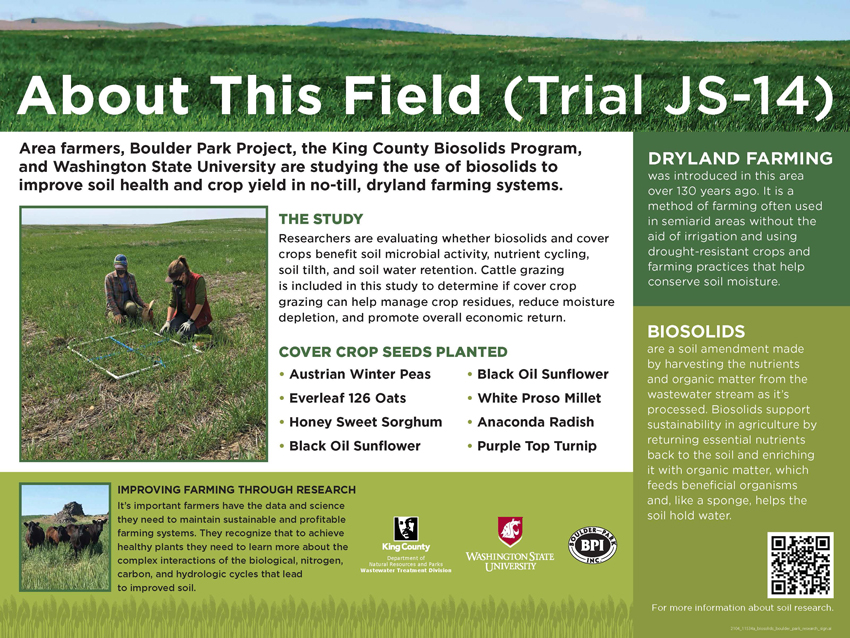

WSU soil scientists are conducting farmland research at our project site in Eastern Washington, evaluating the soil health benefits of biosolids and cover cropping, including studying any impacts of cattle grazing. Learn more about WSU research.

Our research partners

Our long-standing research partnerships ensure effective third-party review and oversight. Researchers and scientists conduct studies that allow us to track the benefits of biosolids and provide quality assurance to our customers and regional landowners. These partners play a crucial role in exploring beneficial uses of biosolids and support our new product development efforts.

Translate

Translate